The RATP, with more than a century of existence, is a good example of continuity and sustainability.

The LN luminaire, designed to meet the needs of the Régie Autonome des Transports Parisiens, was therefore developed in this spirit of solidity and long-term vision.

In this context, the lifespan is essential and the design of the whole has been designed for a period of 30 years.

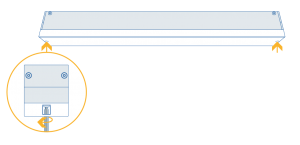

Mounting from below in the cove, system installed in the false ceiling.

Corridor, place of passage for travellers.

Of course, like fluorescent luminaires, certain parts will have to be changed during this period of time and very close attention has therefore been paid to maintainability.

An effective luminaire currently must be designed with LEDs because they are by far the most efficient sources. This has two implications:

-

on the one hand electronic components and circuits which have a limited lifespan so that it is necessary to be able to change from time to time

-

on the other hand, an optic to attenuate the strong luminance of LEDs, i.e. a diffuser which also serves to seal the luminaire. However, it must be made of polycarbonate so as not to have an exorbitant cost and it ages more quickly than the metal parts, for example.

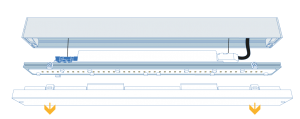

These two elements are therefore designed to be changed throughout the life of the luminaire with a ease extreme maintenance: once the luminaire has been disconnected, 2 very accessible screws – since on the front of the luminaire – allow the cover to be dismantled and these parts fixed by clips and connectors to be changed. Everything is therefore carried out in a minimum of time and for a low frequency of intervention.

As part of this extraordinary luminaire, the supply of these spare parts is guaranteed for 30 years: do not hesitate to contact us if you have any questions.

Maintenance of the platinum block

1. Separate the plate block and the cover by removing the screws (M4 rounded head, tamper-proof TORX recess) with a T20 tamper-proof TORX screwdriver.

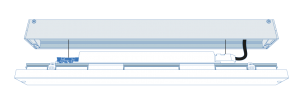

2. The plate and the bowl are one unit. They remain attached to the body thanks to the safety ropes.

3. Maintenance is easily done by orienting the platen block.

Remove the driver block: CHC M4 screw, hexagonal recess with a BTR key n°2.5.

Disconnect the connectors: flat screwdriver.

LED maintenance

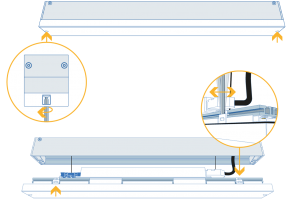

1. Separate the plate block and the cover by removing the screws (M4 rounded head, tamper-proof TORX recess) with a T20 tamper-proof TORX screwdriver.

2. Unclip the cover from the plate using a thin, flat tool (flat screwdriver).

3. Remove the bowl. Changing LEDs is easy.